Our raw material suppliers

Film

Chemosvit Folie s.r.o (Slovakia)

Blown polyethylene films based on LDPE, LLDPE, HDPE polymers: transparent and white.

Plastchim-T (Bulgaria)

Coextruded non-oriented films (CPP), biaxially oriented polypropylene films - BOPP films (transparent, metallized, white, pearl, matte)

Flex (Poland)

Biaxially oriented polyethylene terephthalate films (transparent, metallized, matte, with a twist effect)

Paint

Plates for flexographic printing

Print preparation area

The prepress process is very important, because at this stage specialists determine and shape the final form of the finished product.

Tatrafan LLC has its own graphic studio for adaptation and design, production of digital polymer forms for printing.

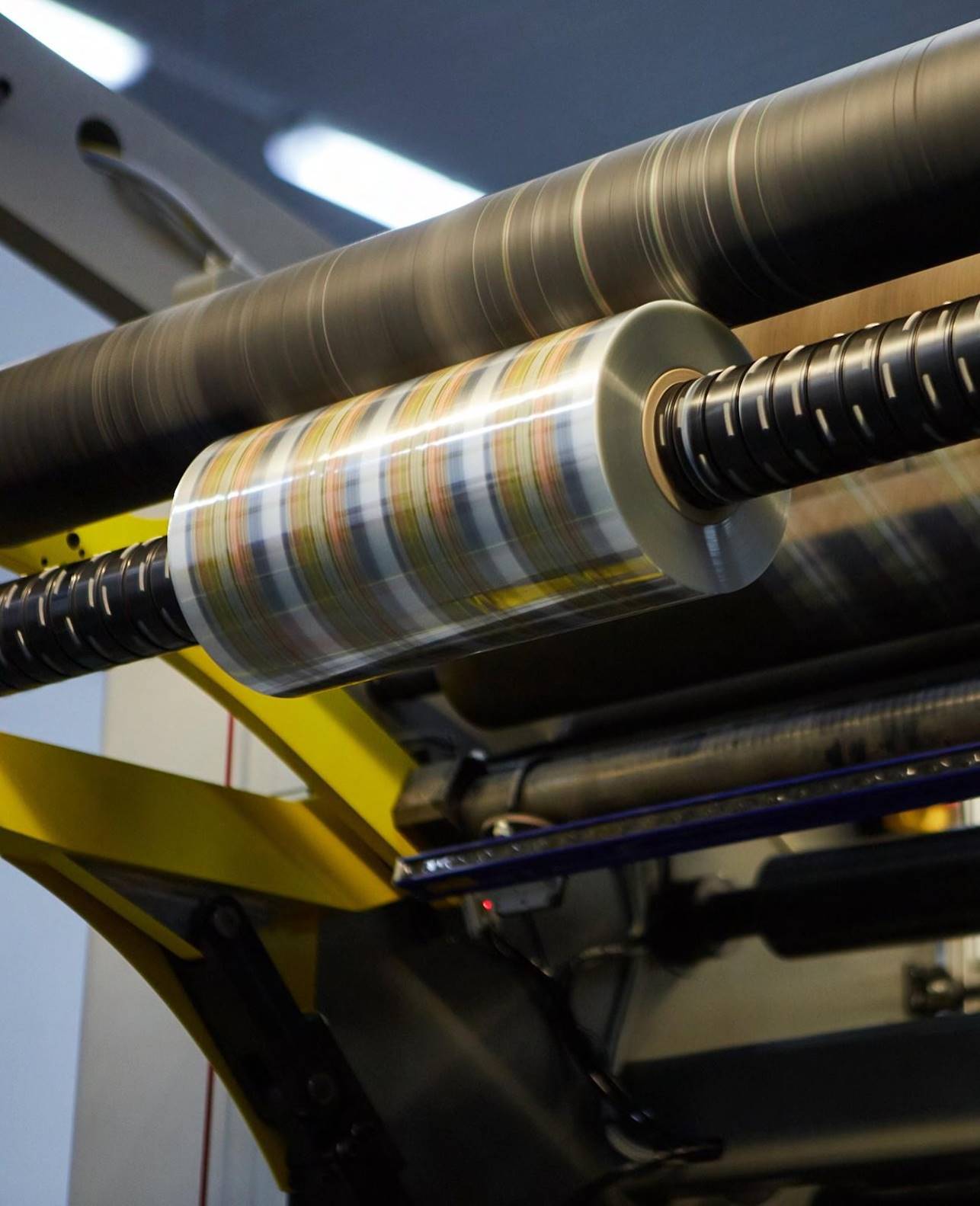

Flexoprinting

For flexo printing, Tatrafan uses Comexi printing machines, which are designed with the patented FLEXO Efficiency concept in mind, which is ergonomic, easy to operate and maintain. It allows printing up to eight colors: on film, paper, applying a lacquer coating. The print width is up to 1250 millimeters.

Lamination

Lamination at the plant is carried out using Comexi laminators. These are high-end laminators designed according to two key concepts: versatility and highest performance. They provide: lamination width up to 1310 millimeters, adhesive lamination up to 4 layers, solvent-free and solvent lamination. It is possible to apply cold glue (cold seal)

Bags

Tatrafan LLC is equipped with a high-performance packing machines with internal adhesive reinforcement LEMO INTERmat ST-SA 850. The technology allows to produce packages with a bottom fold, with a rounded and straight bottom. It is also possible to perforate the valve (the so-called tear-off valve, which is used in manual packaging of goods). At the same time, the machine makes perforated round holes (for air access) and notches on the packages.

Slitting

LLC "Tatrafan" is equipped with high-performance Soma slitting machines capable of cutting laminated films and monofilms with a thickness ranging from 8 to 200 microns

Laboratory

The company has its own laboratory, where products are tested for compliance with quality standards using specialized equipment, including a tensile testing machine, laboratory scales, a thickness gauge, a film sealing device, and other instruments.

Ink Mixing Station

One of the advantages of LLC "Tatrafan"’s production is its own ink mixing station by the Italian brand “Inkmaker,” which allows for the rapid preparation of the required color and prompt adjustments. The equipment ensures accurate color matching and automatic ink dosing. It supports work with the Pantone Matching System.

Additional features

Selective varnishing

coating certain areas of the packaging surface with varnish, which helps to achieve the desired product design of the product and gives it a more attractive appearance.

Cold seal

is a water-based coating used to seal a variety of packaging materials. Cold seal technology is used for packaging that should not be exposed to high temperatures. It only requires pressure to seal the adhesive layer, which is pre-applied to the packaging film. Cold seal is suitable for confectionery products made of chocolate and chocolate-containing products, cereal bars, ice cream, etc.

Contacts

Leave your inquiry, and we will get in touch with you! Or feel free to visit us in person.

Our address

Rivnenska street, 76a, Lutsk, Volyn region, 43000

Our Email

saleflex@tatrafan.uaChief of Sales Departmentlilia.pinchuk@tatrafan.uaSales manager vadym.moroziuk@tatrafan.uaPurchase departmentserhiy.kozak@tatrafan.ua

Our phone number

+380332785999Labor Economics Department hr@tatrafan.ua

+380332788187

+380503723031